Mar.10.2023

Part I: Leather and PU Fabric Edge-Wrapping Techniques

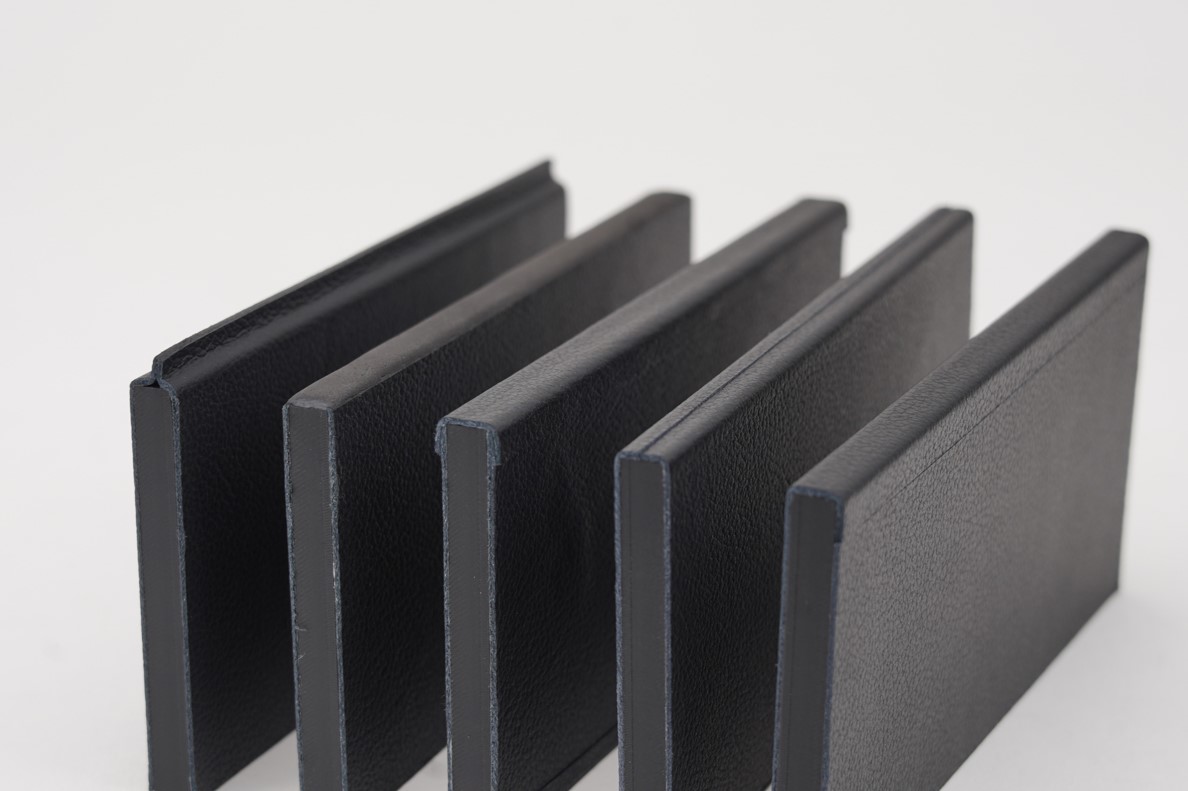

Wrapping leather or fabric results in the ends meeting at an edge, which exposes the material's inner composition. To address this, different edge-wrapping techniques are used to treat the edges. Leather and PU fabric edge-wrapping is where of the unfinished edge se The leather or PU fabric are concealed and adhered to improve the product's appearance and durability. There are five common edge-wrapping techniques: front and back wrapping, edge coating, outer wrapping, edge-to-edge wrapping, and backside overlap wrapping. Two of the most commonly employed methods for electronic products are front and back wrapping and edge coating. More details on these two techniques are provided in the following sections. The three other techniques are used in more specific situations and will be delved into furthering in an II.

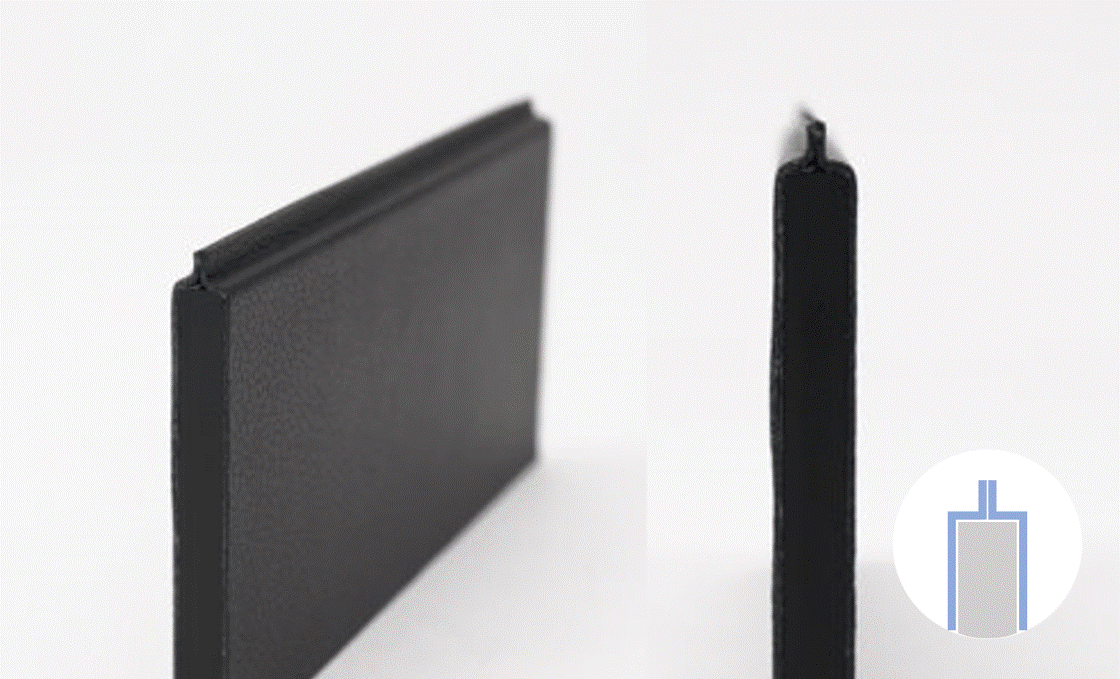

Technique 1: Front and back wrapping

This common edge-wrapping technique is often used in mass production and involves joining and adhering the front and back pieces together at the edge using a jig.

Process: The front and back pieces of the leather or PU fabric adhere to the product's core. Then the excess front and back seams adhere together at their meeting edge, forming a flap.

Advantage: This edge-wrapping technique has a high production yield.

Disadvantage: The flap affects the appearance of the model.

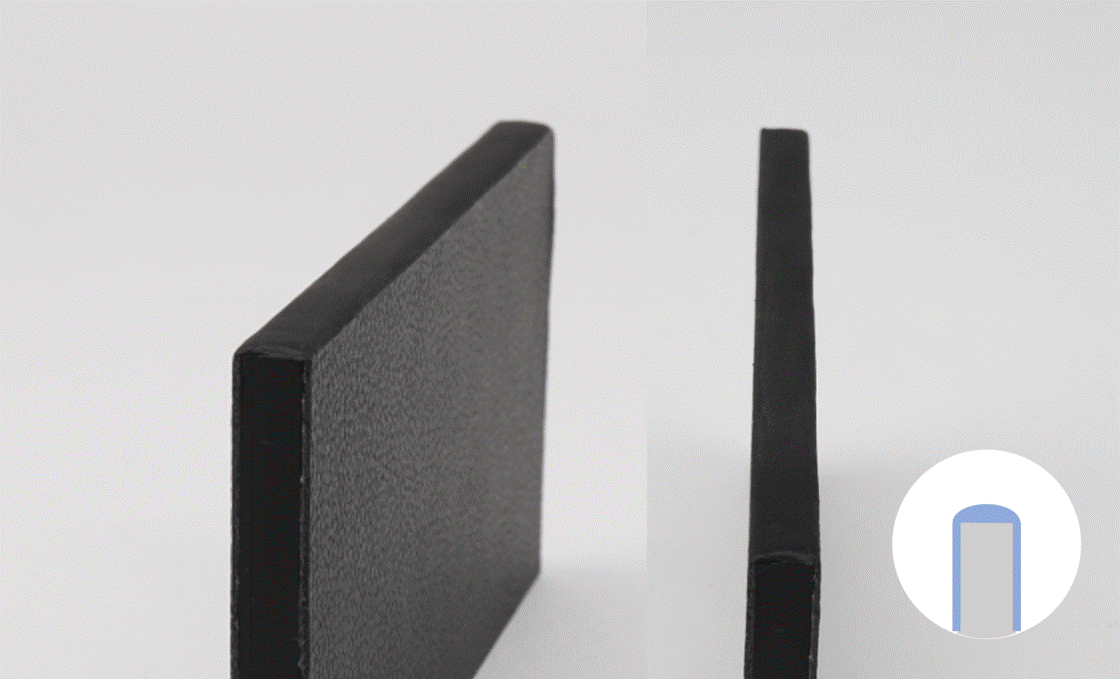

Technique 2: Edge coating

This edge-wrapping technique is the most commonly used for leather, although it can also be used for certain types of PU fabrics. In mass production, this technique can be performed manually or automated.

Process: The front and back pieces of the leather or PU fabric adhere to the product's core at the corner of the edges. The exposed unfinished edge of the product is then covered with resin coating similar to the color of the leather or PU fabric.

Advantage: No special equipment is needed for this edge-wrapping technique, and it can be made manually using simple tools.

Disadvantage: Multiple layers of coating and polishing are required, which is time-consuming, and its edge finishing quality varies depending on workmanship.